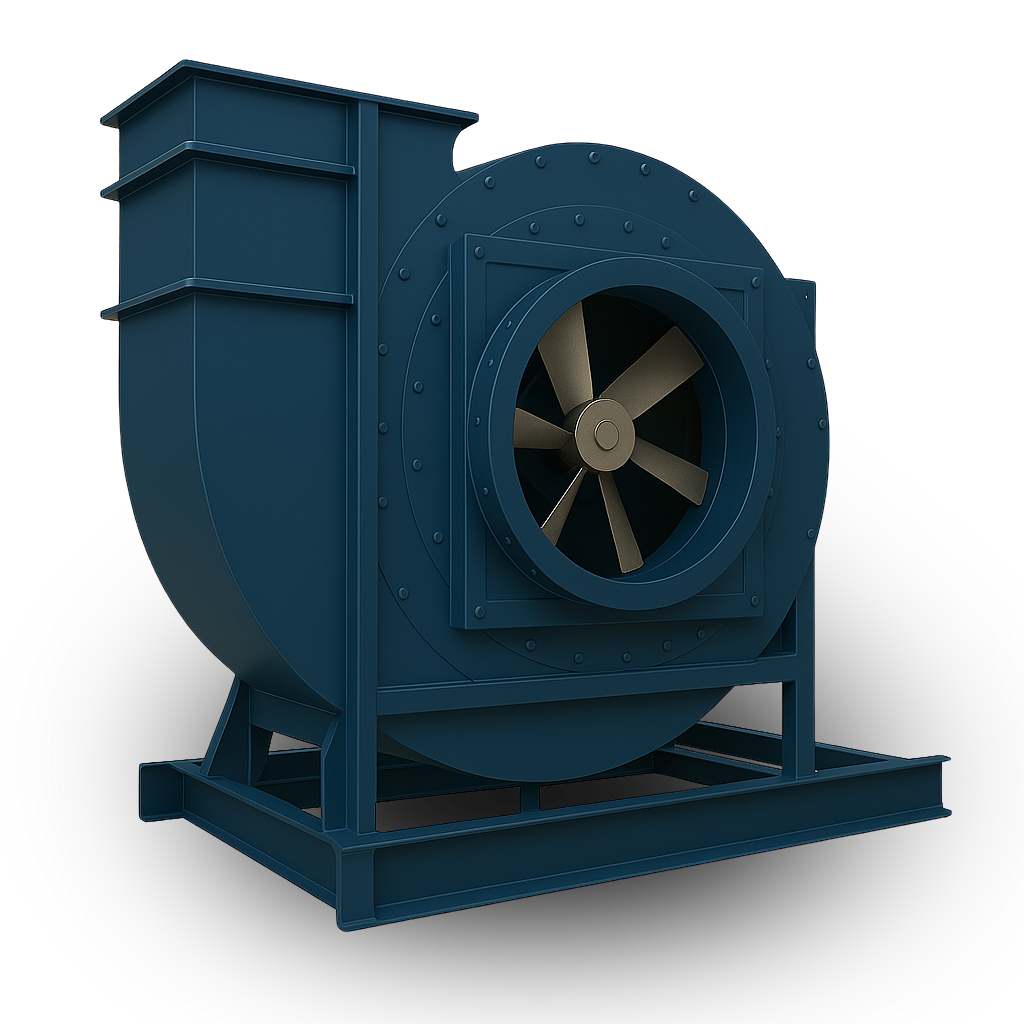

Industrial Centrifugal Fan

Features :

- High Static Pressure Capability: Designed to handle high-resistance systems, centrifugal fans deliver powerful airflow at high static pressures — ideal for ducted ventilation and process air systems.

- Robust Construction: Built with heavy-duty steel or aluminum housing and dynamically balanced impellers for stable, vibration-free performance in demanding industrial environments.

- Efficient Air Handling: Offers precise control over airflow direction and volume, making it suitable for applications requiring targeted or filtered ventilation.

- Low Noise Operation: Engineered with backward- or forward-curved blades and insulated housings to reduce noise levels during continuous operation.

- Customizable Configurations: Available in various sizes, airflow capacities, impeller types (backward, forward, or radial), and mounting options (direct or belt-driven) to suit specific industrial requirements.

- Corrosion & Heat Resistant Options: Models available with coated finishes, stainless steel construction, or high-temperature bearings for use in chemical, food, or high-heat applications.

- Energy-Efficient Performance: Designed for optimal airflow with minimal power consumption, lowering operational costs over time.

- Wide Industrial Applications: Ideal for HVAC systems, dust collection, fume extraction, boiler exhausts, cooling towers, and cleanroom ventilation.

The Industrial Centrifugal Fan is a high-performance air-moving solution engineered for applications that demand powerful airflow, high static pressure, and reliable continuous operation. Designed with dynamically balanced impellers and robust steel or aluminum housings, it ensures stable, vibration-free performance even under heavy industrial workloads. These fans are capable of moving air efficiently through long ducts or filtration systems, making them ideal for HVAC setups, dust collection, fume extraction, boiler exhaust, and cleanroom ventilation. With options for backward-curved, forward-curved, or radial impellers, the fan can be customized to match specific airflow and pressure requirements. Noise reduction is achieved through aerodynamic blade design and optional insulated housings, ensuring quieter operation in sensitive environments. Available in direct-driven or belt-driven configurations, the centrifugal fan also offers corrosion-resistant and high-temperature variants for industries like food processing, chemicals, and pharmaceuticals. Energy-efficient and built for durability, the industrial centrifugal fan is a reliable choice for maintaining air quality, temperature control, and ventilation in demanding industrial settings.

Technical Specifications

| Specification | Details |

| Material | Galvanized Iron/Aluminum/ Stainless Steel / Mild Steel |

| Diameter Range | 100 mm to 1600 mm |

| Thickness | 0.5 mm to 1.2 mm |

| Length | Standard 3 meters |

| Surface Finish | Smooth, Corrosion-resistant |